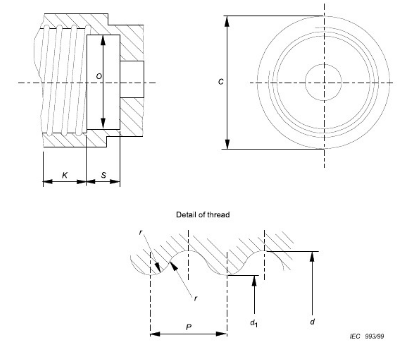

E12/E14/E17/E26/E26d/E27 Holders Torque Gauge

Meet the requirements of IEC60432-1 figure C.2 and IEC60560-2 figure 3.

|

Dimension |

E12 |

E14 |

E17 |

E26 and E26d |

E27 |

Tolerance |

|

C |

15.27 |

20.0 |

20.0 |

32.0 |

32.0 |

Min. |

|

K |

9.0 |

11.5 |

10.0 |

11.0 |

13.5 |

0.0/-0.3 |

|

O |

9.5 |

12.0 |

14.0 |

23.0 |

23.0 |

+0.1/-0.1 |

|

S |

4.0 |

7.0 |

8.0 |

12.0 |

12.0 |

Min. |

|

d |

11.89 |

13.89 |

16.64 |

26.492 |

26.45 |

-0.1/0.0 |

|

d1 |

10.62 |

12.29 |

15.27 |

24.816 |

24.26 |

+0.1/0.0 |

|

p |

2.540 |

2.822 |

2.822 |

3.629 |

3.629 |

– |

|

r |

0.792 |

0.822 |

0.897 |

1.191 |

1.025 |

– |

About the Test Gauges:

1. Lamp cap and Lampholder Gauges are designed according to IEC60061-3,

2. The structure and sharp (thread-like waveform) of gauges for lampcap and lampholder are calculated and optimized via computer, and then processed by computer machine to reach high precision and appearance.

3. The lamp cap and lampholder gauges (go / no go gauge) is made using high-hardness alloy, and handled with QPQ composite infiltration which greatly improves the abilities of rust prevention and wear resistance, the rockwell hardness can reach HR580 above, the service life is more than 3-5 times longer than ordinary gauges.